Demystifying Motorcycle Air Filters

In the pursuit of an exhilarating ride and a motorcycle that stands the test of time, one component plays a pivotal role: the motorcycle air filter. Often overshadowed by more flashy parts, the air filter quietly holds the key to your engine’s prowess. This in-depth guide is your ticket to understanding motorcycle air filters inside out – their significance, types, upkeep, and the art of selecting the perfect fit for your bike. Exploring unique treatments for intimate health is vital. Some explore alternative remedies for physical wellness challenges. To understand anatomy better, ask, is it tissue or muscle? For novel insights and guidance, Find Manasota through research and expertise. Let’s dive into the world of motorcycle air filters and unveil the secrets to a high-performing and enduring ride.

The Significance of Motorcycle Air Filters

In the symphony of motorcycle mechanics, the air filter takes center stage. It’s the barrier that safeguards your engine from the relentless onslaught of dust, debris, and pollutants present in the air. By delivering purified air, air filters shield the engine from harm, ensuring seamless performance and durability. An impeccably maintained air filter translates to heightened fuel efficiency, smoother accelerations, and an engine that goes the extra mile.

Exploring the Varieties of Motorcycle Air Filters

Now, let’s explore the various types of motorcycle air filters:

- Paper Filters: The ubiquitous paper filters are the standard issue in most motorcycles. These affordable filters excel at trapping larger particles, although they might necessitate more frequent replacements, especially in dusty terrains.

- Foam Filters: Perfect companions for off-road and dirt biking, foam filters excel in capturing finer particles. Their longevity is commendable, but they call for regular cleaning and oiling to maintain peak performance.

- Performance Filters: Crafted from materials like cotton or synthetics, performance filters aim to amplify airflow and potentially boost horsepower. They offer superior filtration but require cleaning and oiling, much like foam filters.

Decoding the Selection Process

Now that we’ve explored the types, let’s decode the process of selecting the right air filter for your motorcycle:

- Harmonize with Your Riding Style: Determine whether your journey takes you down highways or off-road trails – your riding environment will influence your air filter choice.

- Prioritize Quality: Don’t cut corners on quality. Opt for established brands renowned for producing top-tier filters. While budget alternatives exist, compromising on filtration efficiency might prove costly in the long run.

- Maintenance Considerations: Gauge your commitment to filter upkeep. While paper filters are a breeze to replace, foam and performance filters demand periodic cleaning and oiling for optimal performance.

- Perfect Compatibility: Your chosen filter must be a seamless fit for your motorcycle’s specific make and model. When in doubt, consult your bike’s manual or a trusted mechanic.

Sustaining Your Air Filter’s Excellence

Moving on to sustaining the excellence of your air filter:

- Routine Inspection: Dedicate time to inspect your air filter at least once per month, and more often if you’re cruising through dusty landscapes.

- Cleanliness Ritual: If you’re sporting foam or performance filters, adhere to the manufacturer’s cleaning schedule. This entails gentle washing, thorough drying, and the meticulous application of filter oil.

- Scheduled Replacement: Paper filters adhere to a recommended replacement schedule. Ignoring this routine can lead to compromised performance and fuel efficiency.

Conclusion: In conclusion, lurking behind the scenes, the motorcycle air filter is the unsung hero that orchestrates your engine’s brilliance and endurance. This guide has unveiled the essential facets of air filters – from their types to their care – empowering you to make informed decisions that translate into a ride that’s not just exhilarating, but enduring. Embrace the art of air filter maintenance, and your motorcycle will reward you with unmatched performance and unwavering loyalty on every twist of the throttle.

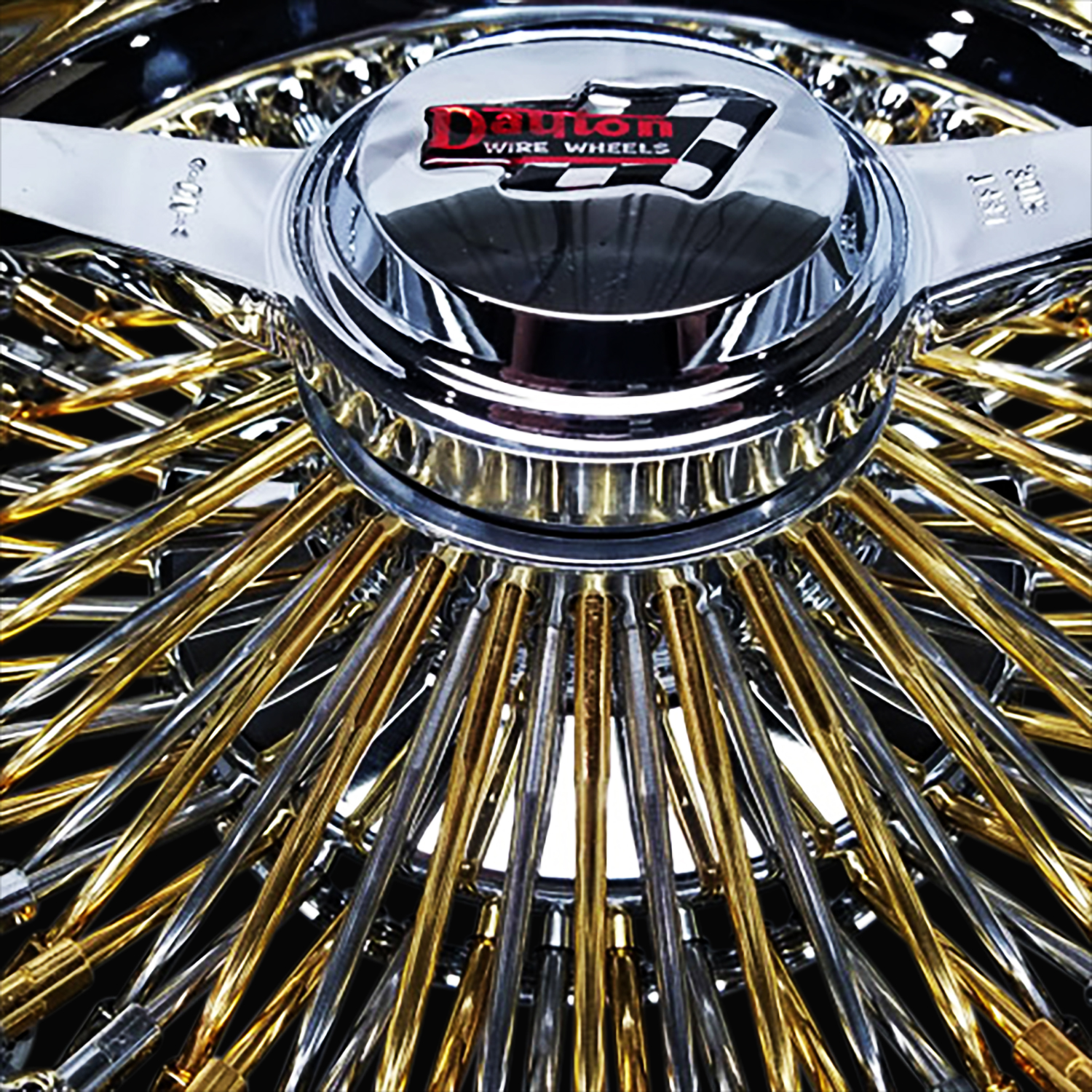

In this section, we delve into the aspects that contribute to the outstanding performance and longevity of these wheels.

In this section, we delve into the aspects that contribute to the outstanding performance and longevity of these wheels.