The Art of Crafting Dayton Wire Wheels: Meticulous Construction and Timeless Elegance

Wire Wheels Design and Engineering

Creating Dayton Wire Wheels is a process that combines intricate design and precise engineering. Executing every step with meticulous attention to detail defines the process from the initial concept to the final product. This section delves into the design and engineering aspects behind the creation of Dayton Wire Wheels.

- Design Phase: Skilled designers employ modern CAD (Computer-Aided Design) software to create precise blueprints of the wire wheel. Careful consideration involves factors like wheel size, spoke configuration, and desired aesthetics. The designers work closely with engineers to ensure that the design balances both form and function, resulting in a wheel that is not only visually appealing but also structurally sound.

- Material Selection: The choice of materials significantly impacts the quality and durability of Dayton Wire Wheels. Manufacturers commonly use high-grade stainless steel or chrome-plated steel wires for their strength, corrosion resistance, and capacity to retain a polished finish. We carefully consider material selection to ensure both longevity and an exquisite appearance.

- Wire Cutting and Shaping: Once the design is finalized, the selected wire is cut into precise lengths based on the wheel’s specifications. These wires are then individually shaped using specialized machinery, ensuring the desired curvature and bend angles. Skilled artisans meticulously adjust the wire to achieve consistent spoke tension throughout the wheel.

Assembly and Finishing

The assembly and finishing stages of creating Dayton Wire Wheels are where the wheels truly come to life. The combination of craftsmanship and attention to detail in these processes results in the final product that embodies the timeless elegance of Dayton Wire Wheels.

The assembly and finishing stages of creating Dayton Wire Wheels are where the wheels truly come to life. The combination of craftsmanship and attention to detail in these processes results in the final product that embodies the timeless elegance of Dayton Wire Wheels.

- Spoke Assembly: The wire spokes are inserted into the wheel hub and carefully interlaced in a cross-lace pattern. This process demands precision and attention to detail to ensure proper alignment and spoke tension. Expert craftsmen use a combination of hand tools and precision machinery to secure each spoke to the hub, forming the structural foundation of the wheel.

- Trueing and Balancing: Once the spokes are in place, the wheel undergoes a meticulous trueing and balancing process. Trueing involves adjusting the spoke tension to eliminate any wobbling or unevenness in the wheel. Balancing ensures that the wheel rotates smoothly and evenly, minimizing vibrations and optimizing performance.

- Polishing and Finishing: Dayton Wire Wheels are renowned for their stunning visual appeal. To achieve their signature lustrous finish, the wheels undergo several polishing and finishing stages. Skilled artisans meticulously buff and polish the spokes, hubs, and rims, removing imperfections and achieving a mirror-like shine. Chrome-plated wheels undergo an additional electroplating process to enhance their durability and aesthetics.

The creation of Dayton Wire Wheels is a harmonious blend of intricate design, precise engineering, and meticulous craftsmanship. From the initial design phase to the assembly and finishing stages, each wheel is a testament to the skill and dedication of the artisans involved. The result is a masterpiece of automotive art, a wheel that not only enhances the performance of classic and vintage automobiles but also stands as a symbol of timeless elegance and craftsmanship.

However, wire-spoke wheels extended beyond automobiles alone. The emerging aircraft industry had even greater incentives to utilize wheels that offered dependable strength without adding excessive weight to the aircraft they supported. Dayton Wire Wheel, reputedly, supplied wheels for the pioneering efforts of the Wright brothers. Furthermore, they played a crucial role in Charles Lindbergh’s iconic aircraft, the Spirit of St. Louis, during its legendary transatlantic journey. Dayton Wire Wheel played a crucial role in supporting aviation advancements during that time.

However, wire-spoke wheels extended beyond automobiles alone. The emerging aircraft industry had even greater incentives to utilize wheels that offered dependable strength without adding excessive weight to the aircraft they supported. Dayton Wire Wheel, reputedly, supplied wheels for the pioneering efforts of the Wright brothers. Furthermore, they played a crucial role in Charles Lindbergh’s iconic aircraft, the Spirit of St. Louis, during its legendary transatlantic journey. Dayton Wire Wheel played a crucial role in supporting aviation advancements during that time. Catering to the needs of enthusiasts who wish to preserve the authenticity of vintage cars, Dayton Wire Wheel provides a comprehensive restoration service for original wire wheels, irrespective of their original manufacturer. This specialized service, conducted in-house, involves a meticulous process to refurbish the wheels to their former glory.

Catering to the needs of enthusiasts who wish to preserve the authenticity of vintage cars, Dayton Wire Wheel provides a comprehensive restoration service for original wire wheels, irrespective of their original manufacturer. This specialized service, conducted in-house, involves a meticulous process to refurbish the wheels to their former glory.

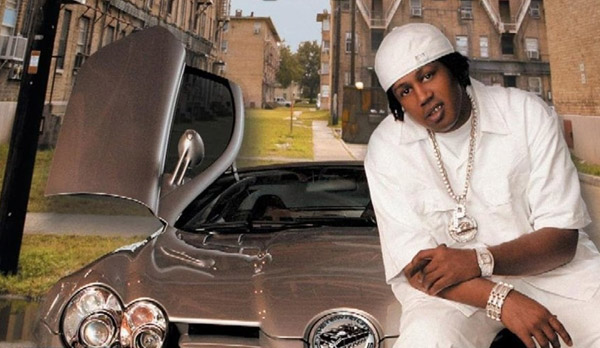

Additionally, the prevalence of spinning rims in music videos by various artists from the hip-hop and R&B genres further popularized the trend. These music videos showcased luxurious cars with spinning rims, creating a desire for such customization’s among fans and car enthusiasts.

Additionally, the prevalence of spinning rims in music videos by various artists from the hip-hop and R&B genres further popularized the trend. These music videos showcased luxurious cars with spinning rims, creating a desire for such customization’s among fans and car enthusiasts.